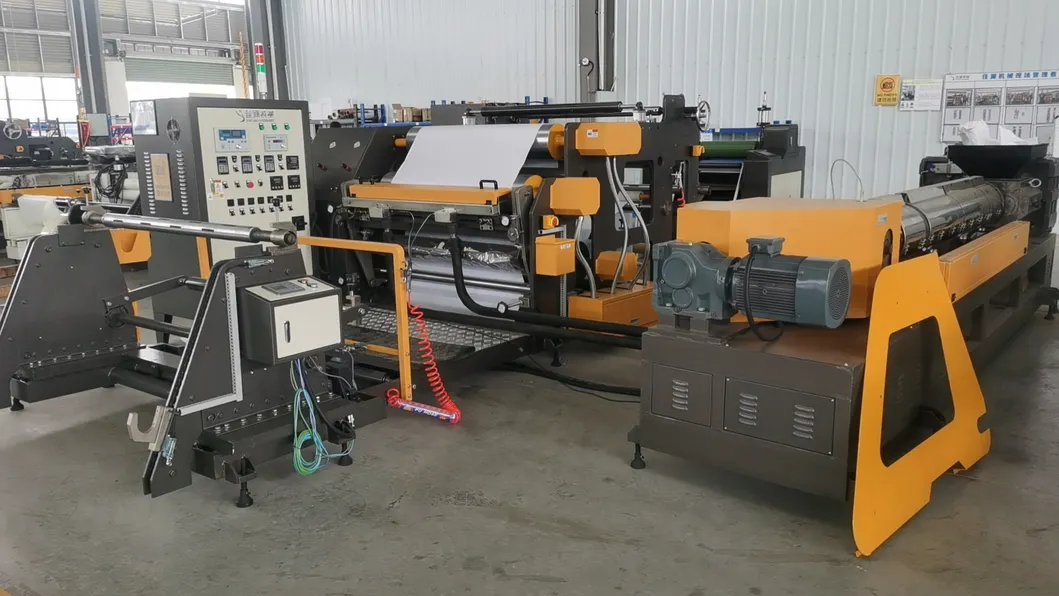

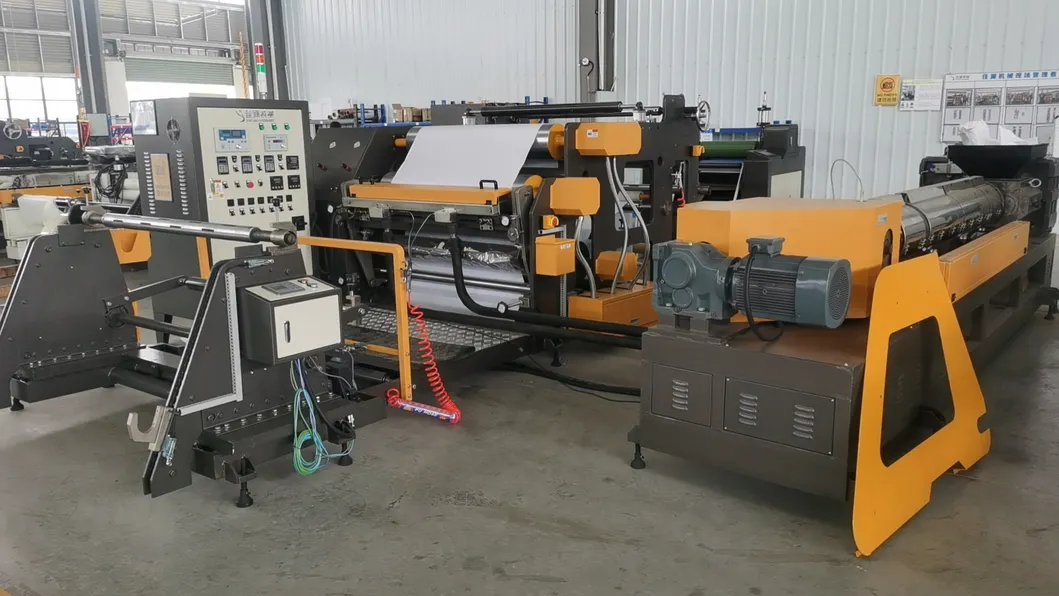

Huashida sản xuất máy móc sản xuất băng keo chống ăn mòn thi công nguội PE được thiết kế để bảo vệ đường ống khỏi bị ăn mòn trong các ngành dầu khí, hóa dầu và nước.

Dây chuyền sản xuất tích hợp ép màng PE, tráng keo cao su butyl và xẻ rãnh tự động, cung cấp giải pháp hoàn chỉnh để sản xuất băng quấn đường ống PE hiệu suất cao.

Quy trình công nghệ

Quy trình sản xuất băng keo chống ăn mòn thi công nguội

Quy trình sản xuất băng keo chống ăn mòn thi công nguội thường bao gồm ba giai đoạn chính: ép màng nền, tráng keo và xẻ rãnh & đóng gói. Mỗi bước được thiết kế để đảm bảo tính đồng nhất của sản phẩm, hiệu suất bám dính và độ bền lâu dài.

1. Ép màng nền

Chuẩn bị nguyên liệu:

Hạt Polyethylene (PE) được sử dụng làm nguyên liệu chính cho màng nền. Nguyên liệu thô được chuẩn bị cẩn thận để đảm bảo độ tinh khiết và chất lượng ổn định.

Tạo hình bằng ép:

Vật liệu PE được nung nóng và làm tan chảy trong máy ép, sau đó được ép qua khuôn để tạo ra một màng liên tục với cấu trúc ổn định.

Làm mát và hiệu chuẩn:

Màng nóng chảy được đưa qua các trục làm mát, giúp làm đông đặc và định hình màng để đạt được độ dày đồng đều và các đặc tính bề mặt nhẵn.

2. Tráng keo

Chuẩn bị keo:

Keo gốc cao su butyl được pha trộn để đạt được độ nhớt, độ dính và độ ổn định cần thiết để có hiệu suất liên kết tối ưu.

Ứng dụng tráng:

Keo đã chuẩn bị được tráng đều lên một hoặc cả hai mặt của màng nền PE bằng thiết bị tráng chính xác, tạo thành một lớp keo đồng nhất và đồng đều.

3. Xẻ rãnh và đóng gói

Thiết lập xẻ rãnh:

Cuộn màng đã tráng được nạp vào máy xẻ rãnh và các thông số cắt được điều chỉnh theo thông số kỹ thuật chiều rộng băng mong muốn.

Vận hành xẻ rãnh:

Màng đã tráng keo rộng được xẻ thành các cuộn băng thi công nguội hẹp, đảm bảo các cạnh sạch và kích thước chính xác.

Quấn và đóng gói cuối cùng:

Các băng đã hoàn thiện được cuộn thành cuộn, kiểm tra cẩn thận, đóng gói và chuẩn bị để lưu trữ hoặc vận chuyển.

Thông số sản phẩm

Dây chuyền ép tệp cơ sở PE

|

Tên thiết bị |

Số lượng |

| 1 |

Bộ nạp tự động chân không |

1 |

| 2 |

Máy sấy phễu |

1 |

| 3 |

Máy đùn SJ-75X30 |

1 |

| 4 |

Bộ đổi lưới thủy lực |

1 |

| 5 |

Khuôn đầu khuôn loại 1000 |

1 |

| 6 |

Máy đúc băng nhiều con lăn |

1 |

| 7 |

Máy quấn |

1 |

| 8 |

Hệ thống điều khiển máy tính PLC |

1 |

Máy tráng keo

| Số |

Tên thiết bị |

Số lượng |

| 1 |

Khung |

1 bộ |

| 2 |

Phanh bột từ tính 200N·M + Thanh silicon 1300mm với bộ xử lý corona |

1 bộ |

| 3 |

Phanh bột từ tính 100N·M |

1 bộ |

| 4 |

Khớp ly hợp bột từ tính 100N·M |

2 bộ |

| 5 |

Khớp ly hợp bột từ tính 200N·M |

1 bộ |

| 6 |

Vít |

1 bộ |

| 7 |

Thiết bị nạp cưỡng bức |

1 bộ |

| 8 |

Hệ thống áp suất không đổi |

1 bộ |

| 9 |

Ống dẫn keo |

1 bộ |

| 10 |

Máy quấn |

1 bộ |

| 11 |

Máy tháo cuộn |

2 bộ |

| 12 |

Thiết bị pha trộn |

1 bộ |

| 13 |

Biến tần động cơ chính |

1 bộ |

| 14 |

Biến tần máy đùn |

1 bộ |

| 15 |

Công tắc nhiệt |

1 bộ |

| 16 |

PLC |

1 bộ |

Ưu điểm của chúng tôi

-Áp dụng công nghệ tiên tiến

-Vận hành ổn định

-Tự động hóa cao, tiết kiệm chi phí lao động

-Chất lượng tốt, đáp ứng tiêu chuẩn quốc tế

-Cung cấp giải pháp sản xuất hoàn chỉnh: thiết kế, lắp đặt, chạy thử, đào tạo

-Chia sẻ với bạn 389 bộ kinh nghiệm sản xuất từ khắp nơi trên thế giới

-Có 9 kỹ sư cao cấp chuyên nghiệp

-Có trạm làm việc chuyên gia về thiết bị máy móc nhựa cao cấp tại Trung Quốc

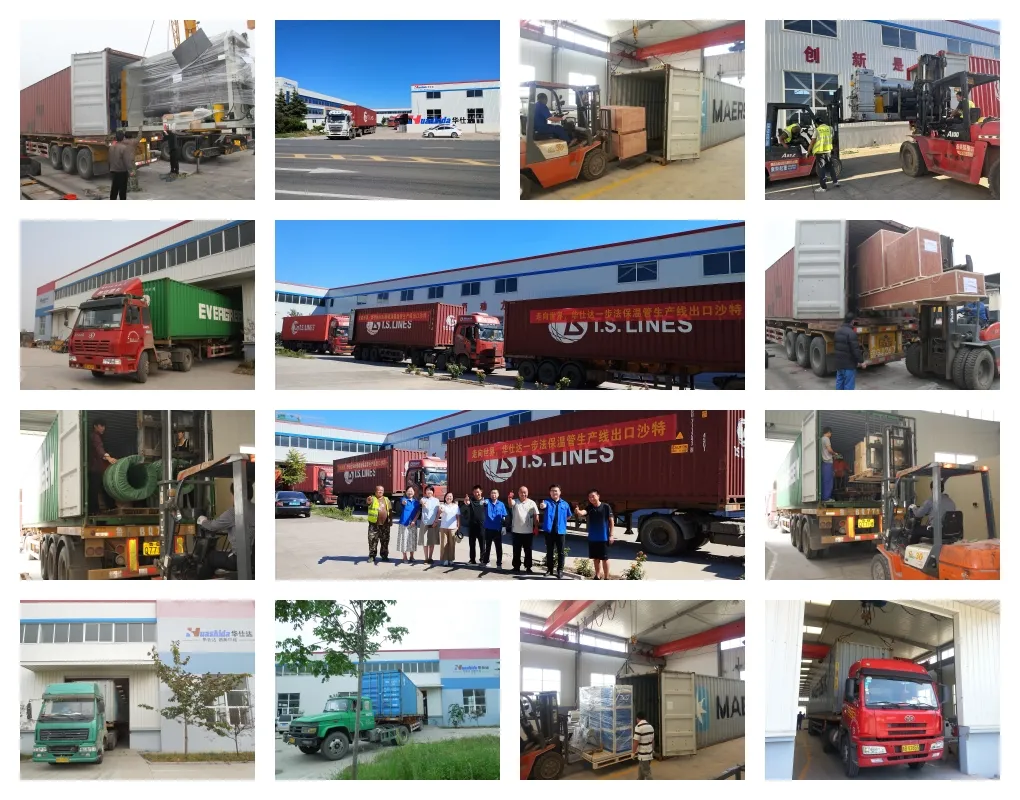

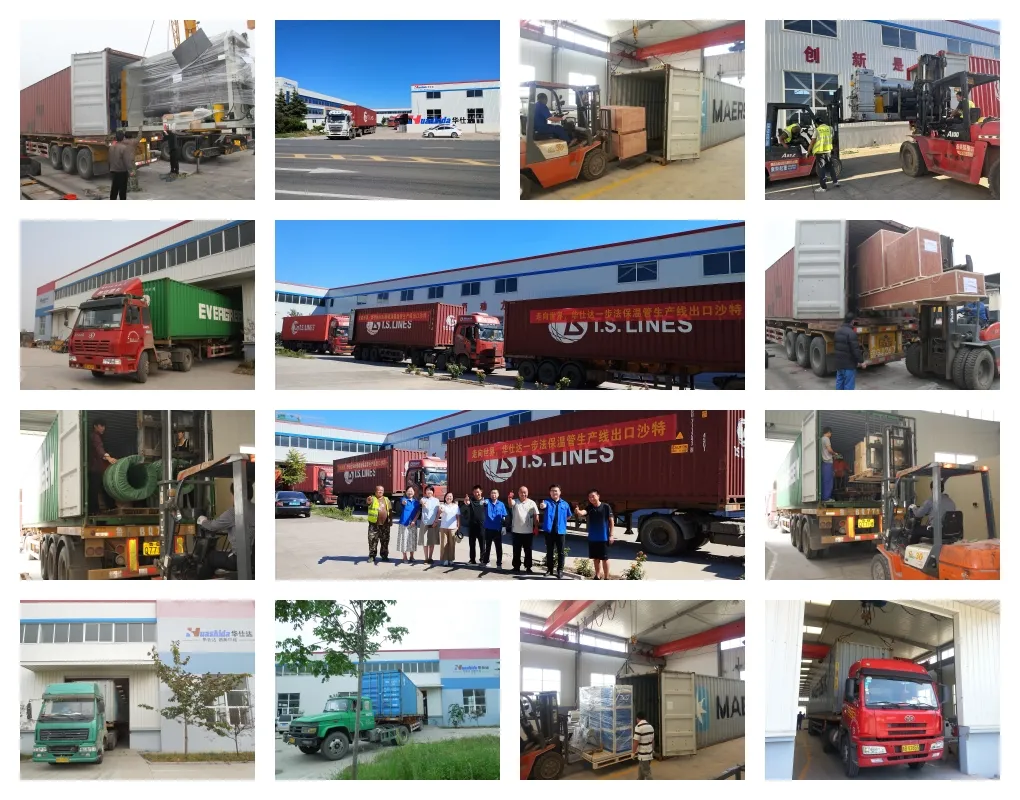

Trường hợp khách hàng

Hồ sơ công ty

Qingdao Huashida Machinery Co., LTD, là nhà sản xuất dòngs của máy ống nhựa, máy ống đô thị, cách nhiệt đường ống&chống ăn mòn máy móc, và khớp nối đường ống&vật liệu chống ăn mòn, với 21 năm kinh nghiệm sản xuất.

Sản phẩm chính của chúng tôi là:

1. Dây chuyền sản xuất ống bọc HDPE cho ống cách nhiệt trước (110-2000mm)

2. Dây chuyền sản xuất ống cách nhiệt trước cứng

3. Dây chuyền sản xuất ống cách nhiệt trước linh hoạt (PERT)

4. Dây chuyền tráng chống ăn mòn FBE/2LPE/3LPE cho ống thép

5. Dây chuyền tẩy gỉ ống thép

6. PE áp lực ống/Ống cấp nước khí dây chuyền sản xuất

6. Dây chuyền sản xuất tấm/tấm/màng địa kỹ thuật PP/PE

7. NBR PVC Tống/tấm cách nhiệt nhiệt

8. Vật liệu và dụng cụ chống ăn mòn đường ống: ống bọc mối nối co ngót nhiệt, ống bọc mối nối hàn điện, súng hàn di động (máy đùn), que hàn PE PP.

Chúng tôi đã làm việc với hơn 400 khách hàng nước ngoài và xuất khẩu sản phẩm của chúng tôi sang Kazakhstan, Uzbekistan, Iran, Thổ Nhĩ Kỳ, Nga, Nigeria và các quốc gia khác.

Đội của chúng tôi

Giao hàng

Triển lãm

Chứng nhận