Hệ thống sản xuất tích hợp cho các đường ống áp suất cung cấp khí nước HDPE

Mô tả sản phẩm

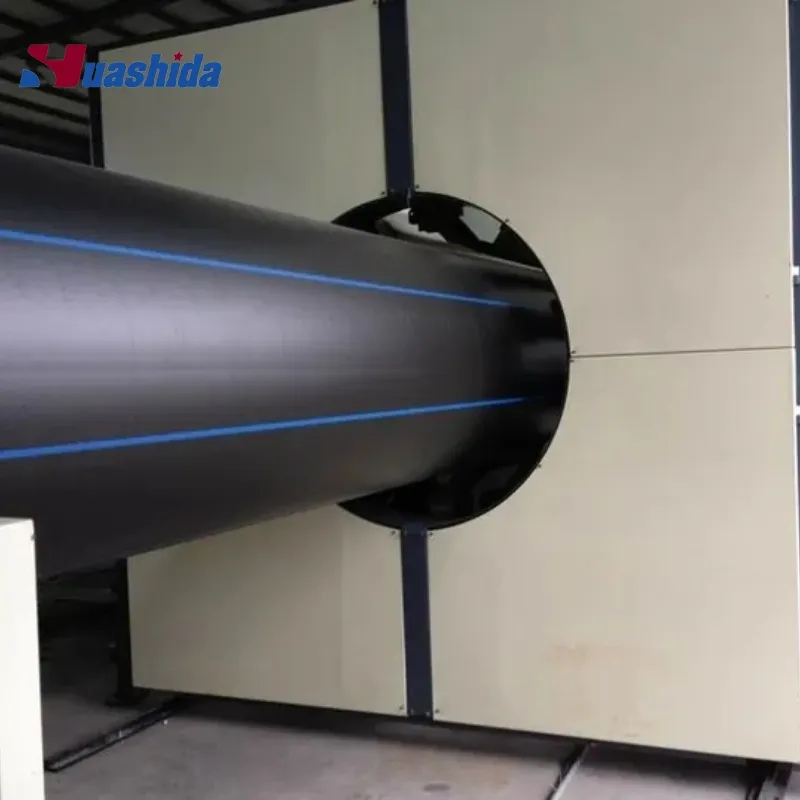

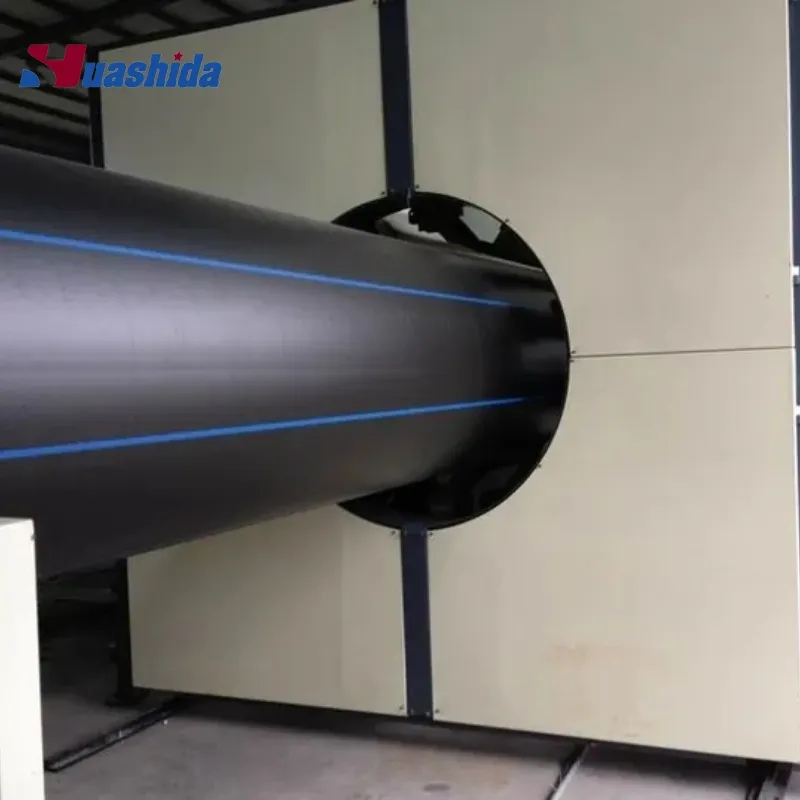

Dòng dây chuyền sản xuất đường ống dẫn nước / khí HDPE hoàn toàn tự động này chuyên sản xuất ống PE80 / PE100 có đường kính từ Φ20mm đến 2000mm, phù hợp với nguồn cung cấp nước đô thị,thủy lợi nông nghiệp và vận chuyển khí đốtĐược trang bị máy ép hiệu suất cao, khuôn chính xác, hệ thống làm mát bằng nước, máy kéo tốc độ cao và máy cắt thông minh, nó đảm bảo kích thước ống chính xác,bề mặt mịn và chất lượng ổn địnhHệ thống điều khiển thông minh PLC nhận ra sản xuất tự động và kiểm tra trực tuyến, có khả năng sản xuất cao, tiêu thụ năng lượng thấp, hoạt động thuận tiện,và tuân thủ môi trườngNó là một giải pháp lý tưởng cho sản xuất ống chất lượng cao.

Thông số kỹ thuật

| Mô hình |

Chiều kính ống |

Đồ vít. |

KiloWatt |

Sản lượng |

| SPEG-110 |

20-110mm |

SJ75X33 |

180kw |

350kg/h |

| SPEG-250 |

63-250mm |

SJ90X33 |

280kw |

500-1000kg/h |

| SPEG-630 |

315-630mm |

SJ120X33 |

522kw |

1000-1200kg/h |

| SPEG-1200 |

710-1200mm |

SJ150X33 |

680kw |

1000-1600kg/h |

| SPEG-2200 |

1000-2200mm |

SJ150X33 |

1200kw |

2000-2500kg/h |

Chi tiết về dây chuyền sản xuất

Các quy trình công nghệ

[Nhiên và sấy] → [Xuất đúc] → [Hình thành khuôn] → [Thản lạnh] → [Nổ và cắt] → [Đánh dấu]

Danh sách thiết bị chính

- 1 bộ máy tải chân không

- 1 bộ máy sấy

- 1 bộ Máy ép một vít hiệu quả cao

- 1set 25/25 một vít extruder cho đường đánh dấu

-1set Bàn hiệu chuẩn chân không

-2/4 bộ bể phun nước

1 bộ Máy kéo

Máy cắt

- Đặt Stacker.

Hình ảnh chi tiết thiết bị

1. Máy đẩy vít đơn

2- Thằng chết đầu.

3. Xăng tạo chân không

4. Thùng làm mát nước

5. Máy kéo ra

6Máy cắt không bụi

7. Khả năng xả

Tính năng

√Đầu đệm xoắn ốc tối ưu hóa việc trộn và giảm nhiệt độ và áp suất làm việc.

√Công nghệ làm mát độc quyền đảm bảo hình tròn của ống ở tốc độ cao.

√Toàn bộ dòng được điều khiển thông minh bởi PLC, với quản lý màn hình cảm ứng tham số.

√Các quy trình như co-extrusion đa lớp giúp giảm chi phí sản xuất.

Hồ sơ công ty

Qingdao Huashida Machinery Co., LTD là một nhà sản xuấtseriess củaMáy ống nhựa, máy ống đô thị,cách ly ống& chống ăn mònMáy, và kết nối ống&vật liệu chống ăn mòn,với 21 năm kinh nghiệm sản xuất.

Các sản phẩm chính của chúng tôi là:

1. HDPE ống áo khoác cho ống cách điện trước dây chuyền sản xuất (110-2000mm)

2. Đường dây sản xuất ống cố định trước cách điện

3. Dòng sản xuất ống cách điện linh hoạt (PERT)

4. ống thép FBE/2LPE/3LPE đường phủ chống ăn mòn

5. Đường tháo ống thép

6. PEáp suấtống/ ống cung cấp nước khídây chuyền sản xuất

6Đường dây sản xuất tấm nhựa PP / PE / tấm / geomembrane

7.NBR PVC Tdây chuyền sản xuất ống/bảng cách nhiệt

8- Vật liệu và dụng cụ chống ăn mòn đường ống: lớp phủ sợi dây chuyền giảm nhiệt, sợi dây chuyền hàn điện, súng hàn di động (extruder), thanh hàn PE PP.

Chúng tôi đã làm việc với hơn 400 khách hàng nước ngoài và xuất khẩu sản phẩm của chúng tôi sang Kazakhstan, Uzbekistan, Iran, Thổ Nhĩ Kỳ, Nga, Nigeria và các nước khác.

Tổng quan về nhà máy

Giao hàng

Triển lãm